Motor Controller Power Density: What is it, and why does it matter?

Summary: Power density is a measure of how much power a motor controller can deliver for its given size. Higher power density makes a controller easier to fit into a vehicle or drone while meeting performance requirements. It also tends to mean a motor controller is more efficient. However, when using this value to compare manufacturers, you need to ensure that the numbers are being calculated using the same conditions.

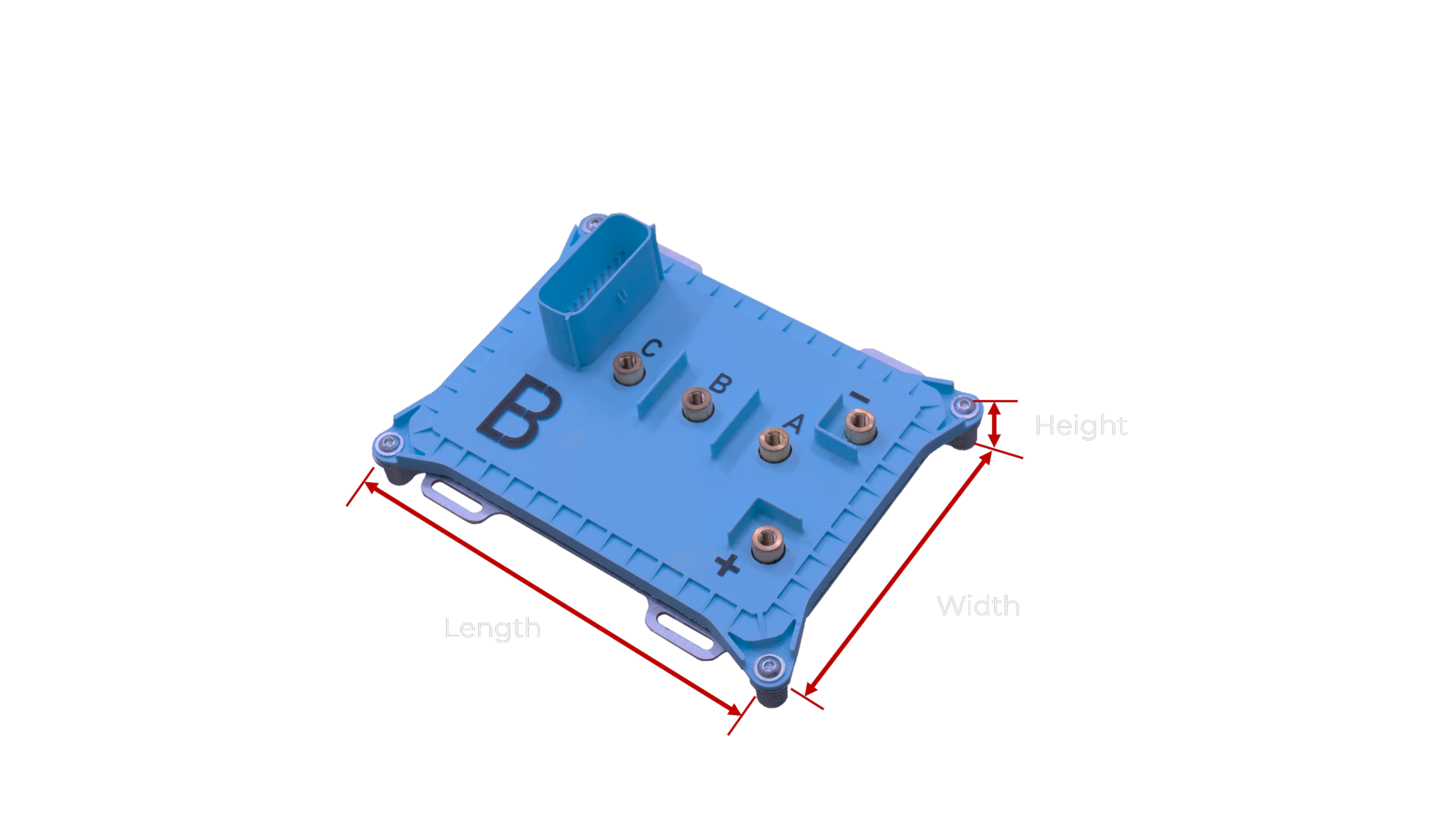

The first question to answer is: what exactly is power density? Mathematically, it is defined as the output power of a motor controller divided by its volume. Usually, this is presented in units of kilowatts per liter (kW/L). There is another value, specific power, defined as the output power of a motor controller divided by its mass (kW/kg) that can also be interesting. Often, motor controller manufacturers will publish this number on a datasheet or their website, because at its core, increasing power density reflects efficient design choices to reduce losses and pack components closer together.

(Length (cm) * width (cm) * height (cm)) / 1000 = Volume (L)

Now, why does this number actually matter? Does it just exist to show off design prowess, or does it lead to real-world benefits?

One benefit is that a more power-dense motor controller allows you to achieve the same level of vehicle performance while taking up less space. That saved space can be used for additional cargo capacity, a larger battery pack, or to shrink the vehicles overall footprint. There’s also greater flexibility in placement, when the controller is more compact, the spaces it can fit into open up, though airflow for cooling needs to remain a consideration.

Another, more subtle, advantage is that a power-dense motor controller is typically a more efficient motor controller. In any design, the heat generated by the internal components must be dissipated. Any motor controller manufacturer is limited by the speed of airflow can be directed over a controller and therefore how much heat can be dissipated. Consequently, more power-dense controllers are typically more efficient as well, resulted in better vehicle range or endurance for the same battery pack.

A third advantage is reduced mass. This advantage comes from better specific power, but that often moves hand-in-hand with power density. This is especially beneficial in any sort of UAV (unmanned aerial vehicle, or drone) application, where that mass savings can be translated into needing less thrust and getting a longer fly time out of the same battery pack. Or, that savings can be used for a larger payload capacity and more operational flexibility.

With all those advantages laid out, there are still some things to take into consideration when evaluating different manufacturers and their claimed power density numbers. The first thing to consider is what DC input voltage the output power is being calculated at. This is because the major driver of losses is the current flowing through the motor controller for a given fixed design. Using the maximum acceptable input voltage for a controller results in the best-case power density, but a more realistic value for a battery-operated vehicle would be to compare controllers at their nominal voltage (i.e. 72V for an 84V max controller).

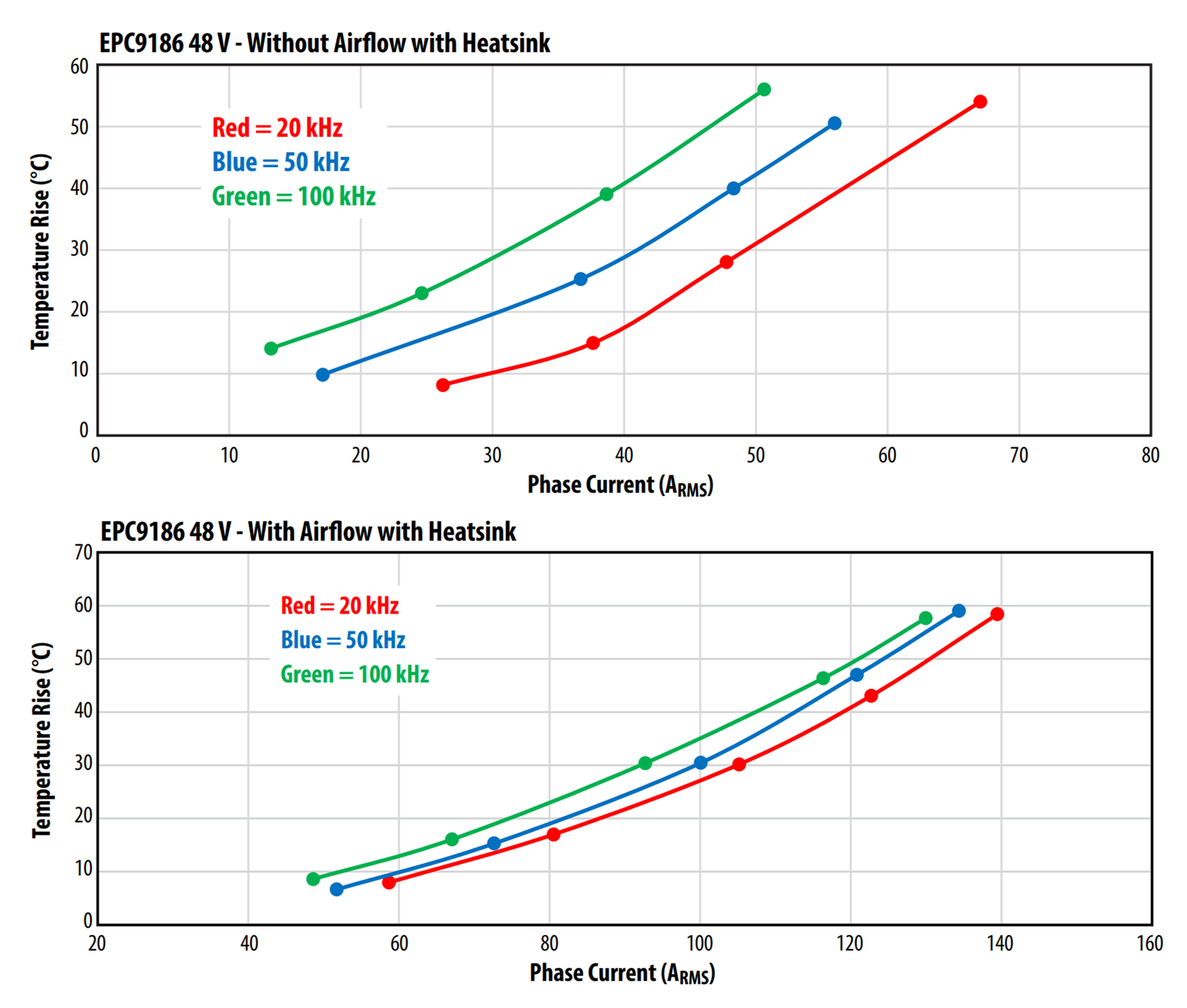

Next, take a closer look at the specified operating conditions. The most obvious is peak versus continuous. This is where it’s important to ensure an apples to apples comparison. Then, it’s a question of what the continuous operating conditions are. Is the temperature at the heatsink specified as a certain value? Which means there must be enough cooling airflow to maintain that value. Is the ambient temperature being specified, and if so, what is it? Is there a specification of how much airflow should be directed at the controller?

Graphs showing the difference in phase current output with and without cooling airflow for a GaN demo board, from: https://epc-co.com/epc/portals/0/epc/documents/guides/EPC9186_qsg.pdf

Also, it is always worth considering how much power density is needed for an application. If the controller is to be placed in a sealed box with a poor connection to an enclosure and no access to ambient air, a lower power density controller may be a better fit for spreading the heat to be dissipated over a larger area.

At Boron Energy, we’ve designed our controllers to deliver to you the benefits of high power density. The high performance and low losses of GaN semiconductors plus our novel cooling integrations allow us to shrink the footprint of our motor controllers while still maintaining high continuous power outputs. If that’s a fit for your application, don’t hesitate to reach out about our off-the-shelf design or a custom GaN motor controller solution.